At Hexco, we have used excavators for sale. Excavators are essential in construction, building, and mining projects due to their ability to handle demanding digging and hauling tasks. Their utilization boosts team productivity and efficiency while reducing operational costs. Available in diverse sizes and types, excavators serve multiple purposes like groundbreaking, trench digging, heavy lifting, pavement crushing, and more.

Also, one should consider buying a used excavator for sale as it is the most budget-friendly option in the market.

To ensure that you have the right excavator that can meet your project requirements and operate at peak efficiency, it is essential to choose the appropriate excavator size and type. This guide will provide you with information on the different excavator types and sizes to help you select the ideal excavator for your project.

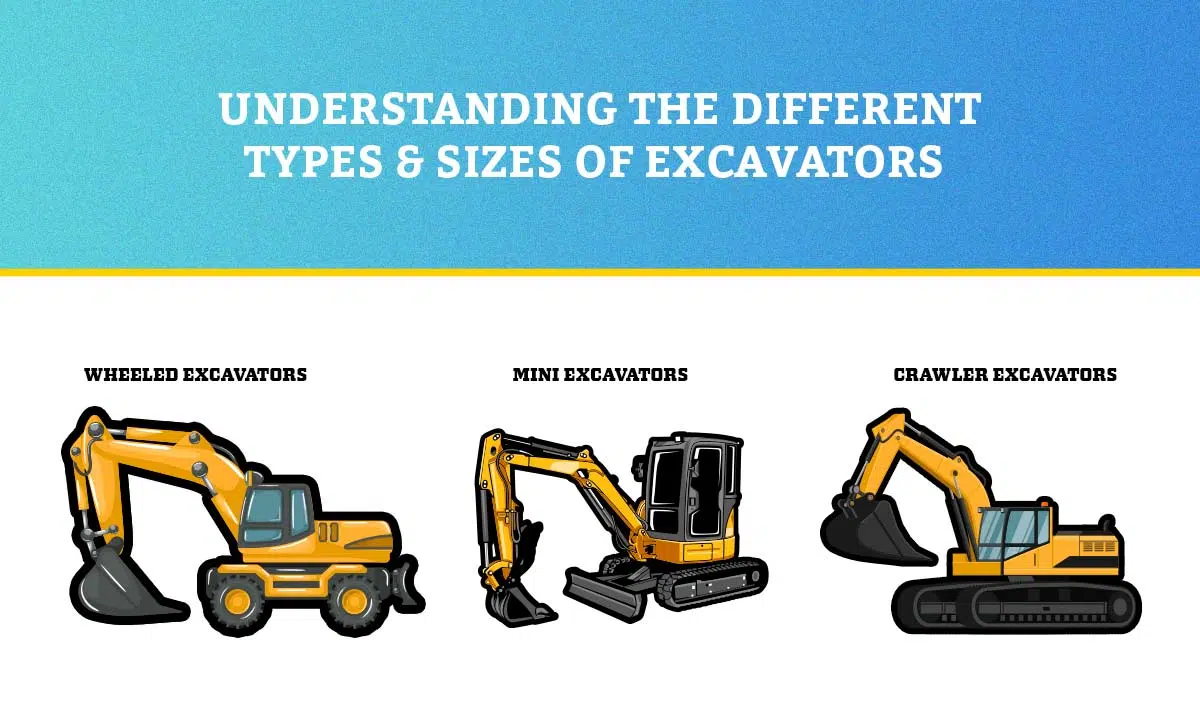

Types of Excavators

Excavators come in various configurations, each suited for specific project needs. Different types excel in heavy-duty work, precise soil extraction, or efficient digging and trenching. With such a wide range of options, finding the perfect excavator for your work site is always possible. Here, we delve into the most common excavator types and their optimal uses.

-

Wheeled Excavator

A wheeled excavator is a variation of the standard excavator that runs on wheels instead of tracks. It excels on solid terrains like asphalt or concrete, making it ideal for such job sites. However, it is less suitable for soft soil or hilly landscapes due to its higher ground pressure and reduced traction. On flat construction sites, wheeled excavators offer easy maneuverability and faster material transportation to dump trucks. Another advantage is that workers can drive them to and from job sites, eliminating the need for trailer transportation. This saves time and reduces costs for your company.

-

Standard Excavator

Excavators with a boom, stick, and bucket can excavate and lift materials. Tracked excavators provide traction on slopes while coming in various sizes and options for excavation, trenching, debris removal, and more. Construction, landscaping, mining, farming, and forestry are among the industries that use these machines.

-

Long-reach Excavator

Extended-reach excavators represent a different type of standard excavator, characterized by an elongated boom and arm. These excavators, equipped with tracks, provide an extended reach, enabling them to handle sizable tasks with enhanced speed and efficiency. They are particularly favored for precision-demanding demolition projects where using a wrecking ball is impractical. Additionally, long-reach excavators prove valuable in excavating hard-to-reach areas, such as along water bodies.

-

Dragline Excavator

Dragline excavators, known as draglines, are heavy-duty machines used for strip mining and canal dredging. They utilize a bucket system that drags the bucket across the surface using wire ropes and chains. The excavated materials are lifted by a hoist rope attached to a suspended boom. To unload, the dragline excavator rotates towards the dump site and releases the bucket.

-

Backhoe Excavator

Backhoe excavators, frequently used in construction, landscaping, and mining, are often mistaken for standard excavators. They are essentially backhoe loaders with an excavator boom at the rear. The front of the backhoe has a large bucket or blade for pushing and leveling soil and materials. Similarly, to standard excavators, the backhoe’s arm operates. However, backhoes have a restricted rotation of 200 degrees, unlike the full 360 degrees of standard excavators.

Considerations When Choosing Excavator Sizes

Work Site Layout

- Mini excavators are suitable for small spaces and sites with hazards.

- Standard or large excavators work well on spacious sites but consider future hazards.

- Tail swing affects maneuverability and proximity to walls or buildings.

Work Site Terrain

- Tracked excavators provide traction on hilly or soft ground.

- Wheeled excavators are ideal for hard and flat surfaces.

- Excavator weight impacts performance and potential site damage.

Project Requirements

- Dig depth, reach, lift height, load capacity, and weight should match project needs.

- Consider future growth and upgrade options.

Transportation and Storage

- Large excavators require special permits and equipment for transportation.

- Mini excavators can be moved using standard trailers.

- Ensure appropriate storage facilities or consider rental options.

Therefore, excavators are crucial for construction, building, and mining projects. Choose the right size and type to meet project requirements and optimize performance. If you’re looking for a reliable and affordable used excavator for sale, our dealership offers a wide selection to meet your construction needs.

Post a Comment